Fieldable Atomic Beam Isotopic Analyzer (FABIA) Instrument:

Mechanical Modifications & Device Implementation

Internship at Los Alamos National Laboratory

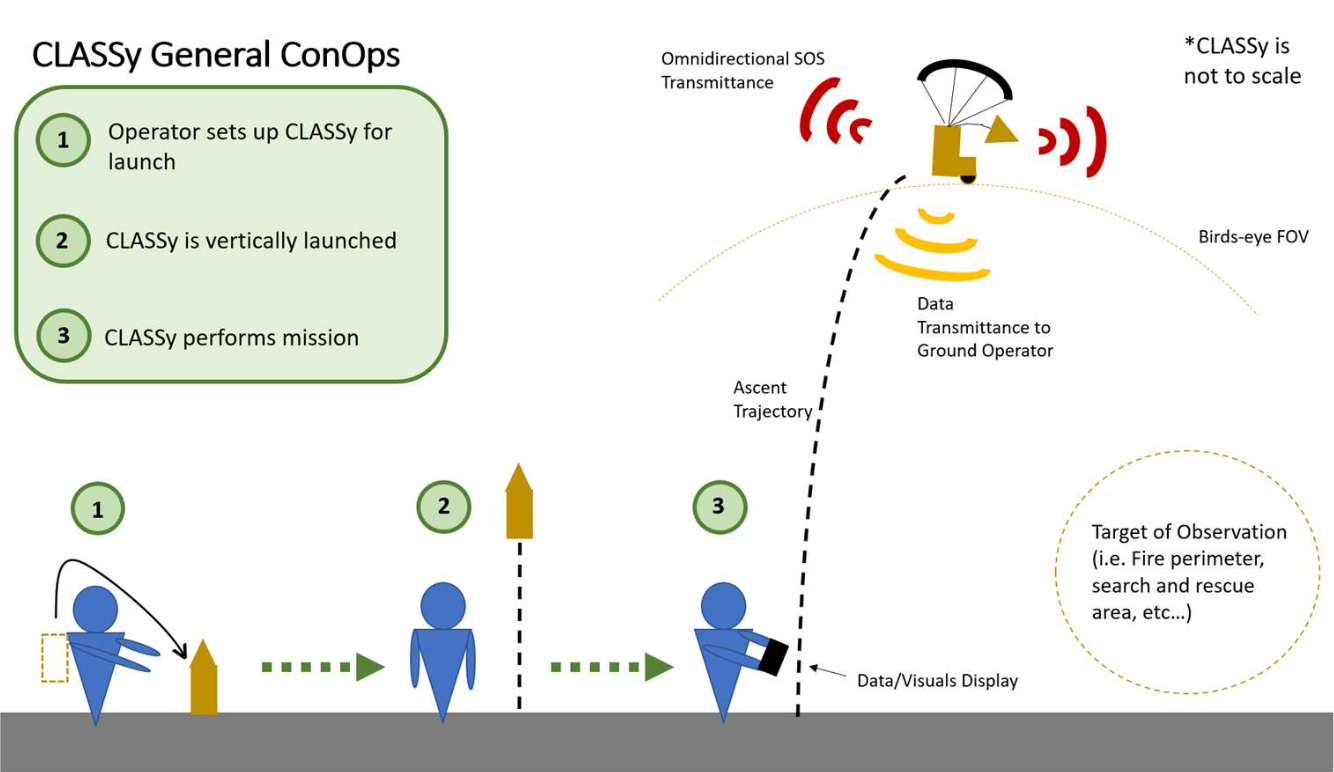

Los Alamos, New MexicoIn the DoE's SULI program, I worked on the Fieldable Atomic Beam Isotopic Analyser (FABIA) under Dr. Alonso Castro in the Actinide Analytical Chemistry (C-AAC) group. I implemented some mechanical re-designs to the main heating components. I also integrated and tested an alternative current controller to drive the onboard laser diode used to perform laser absorption spectroscopy on actinide monatomic beams.

Abstract

I

n the wake of increasing tension and risk

of nuclear conflict, technologies supporting nuclear nonproliferation are

becoming increasingly necessary in upholding safeguards. The International

Atomic Energy Agency (IAEA) emphasizes the importance of developing these

technologies to navigate today’s rapidly evolving nuclear landscape. Efficient

measurement of uranium enrichment in samples sourced from nuclear fuel plants

is central in advancing these technologies. Although mass spectrometry serves

as the current leading analytical tool for this purpose, it faces many

challenges regarding the instrumentation’s cost, size,

weight, analysis time,

and waste generation. As an alternative and solution to the limitations in mass

spectrometry, Los Alamos National Laboratory’s Fieldable Atomic Beam Isotopic

Analyzer (FABIA) utilizes laser absorption spectroscopy to quickly and

accurately determine the isotopic composition of actinide samples in the field.

The instrument works by resistively heating a tantalum micro‐crucible filled

with an actinide sample in near vacuum; it then performs a laser absorption

analysis on the resulting collimated monatomic beam. Per IAEA guidelines and

FABIA’s objectives, several mechanical modifications were implemented to the

copper connecting components that secure the micro‐crucible to the heating

elements. These redesigns eliminated the need for specialized tooling to fasten

the crucible ends and ensured a consistent crucible placement in the

experimental setup. After a series of finite‐element analyses to inspect for

anomalies resulting from changes to these components’ geometries, manufacturing

of the updated component began. Additionally, in the interest of FABIA’s

primary goal of fieldability, the overall weight was reduced by replacing the

original laser power supply with a dedicated current controller to drive the

onboard laser. With these improvements, FABIA is one step closer to being

deployed in the field to monitor the ever‐changing nuclear environment on a

global stage.

LANL Student Symposisum

(Summer 2024)

As well as giving slide-deck presentation at an internal SULI-specific event, I presented my summer's work at the student symposium in poster form.

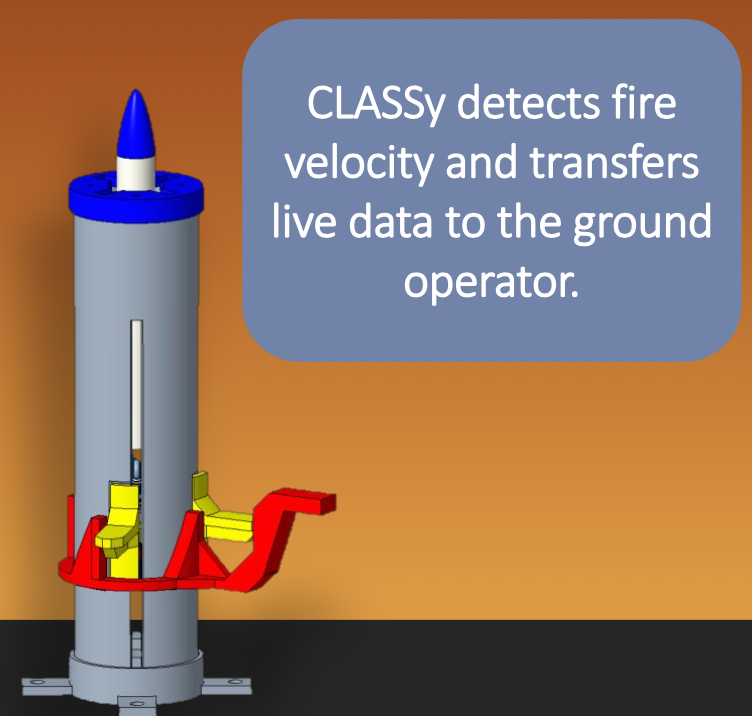

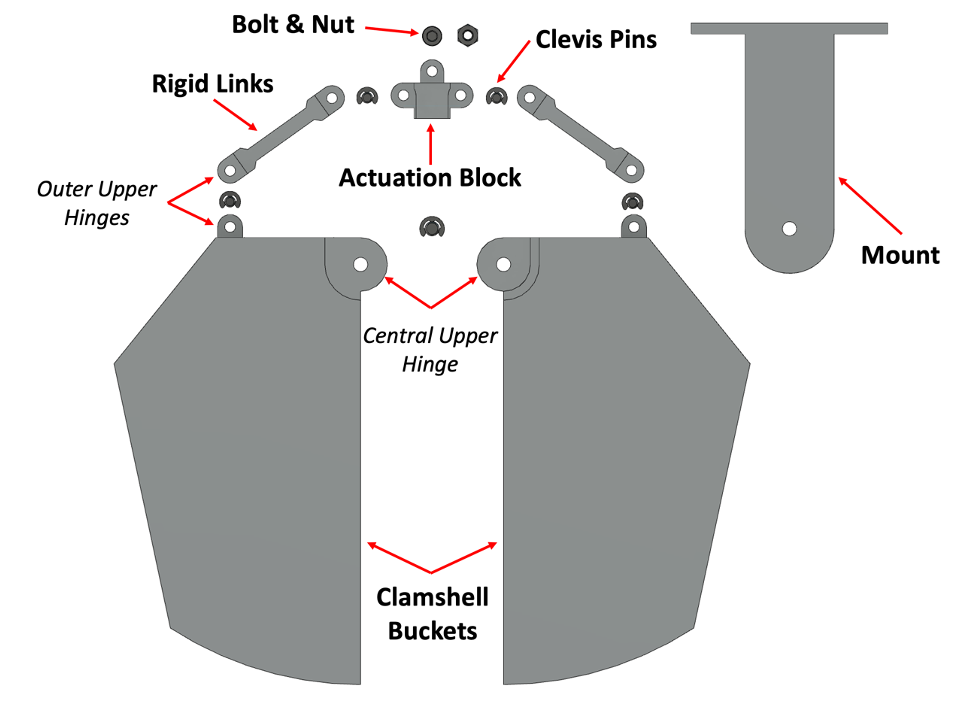

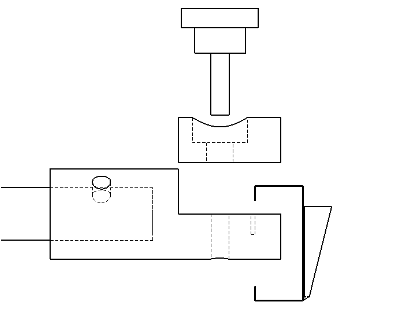

Copper Heating Component Redesign

A major portion of my internship was dedicated to redesigning a component meant to clamp and provide the resistive-heating current to the micro-crucible, which houses the actinide sample. This redesign eliminates the requirement for specialized tooling to secure the crucible and facilitates consistent crucible placement in the clamp. This is a cross-sectional sketch sketch of the updated clamping component design.

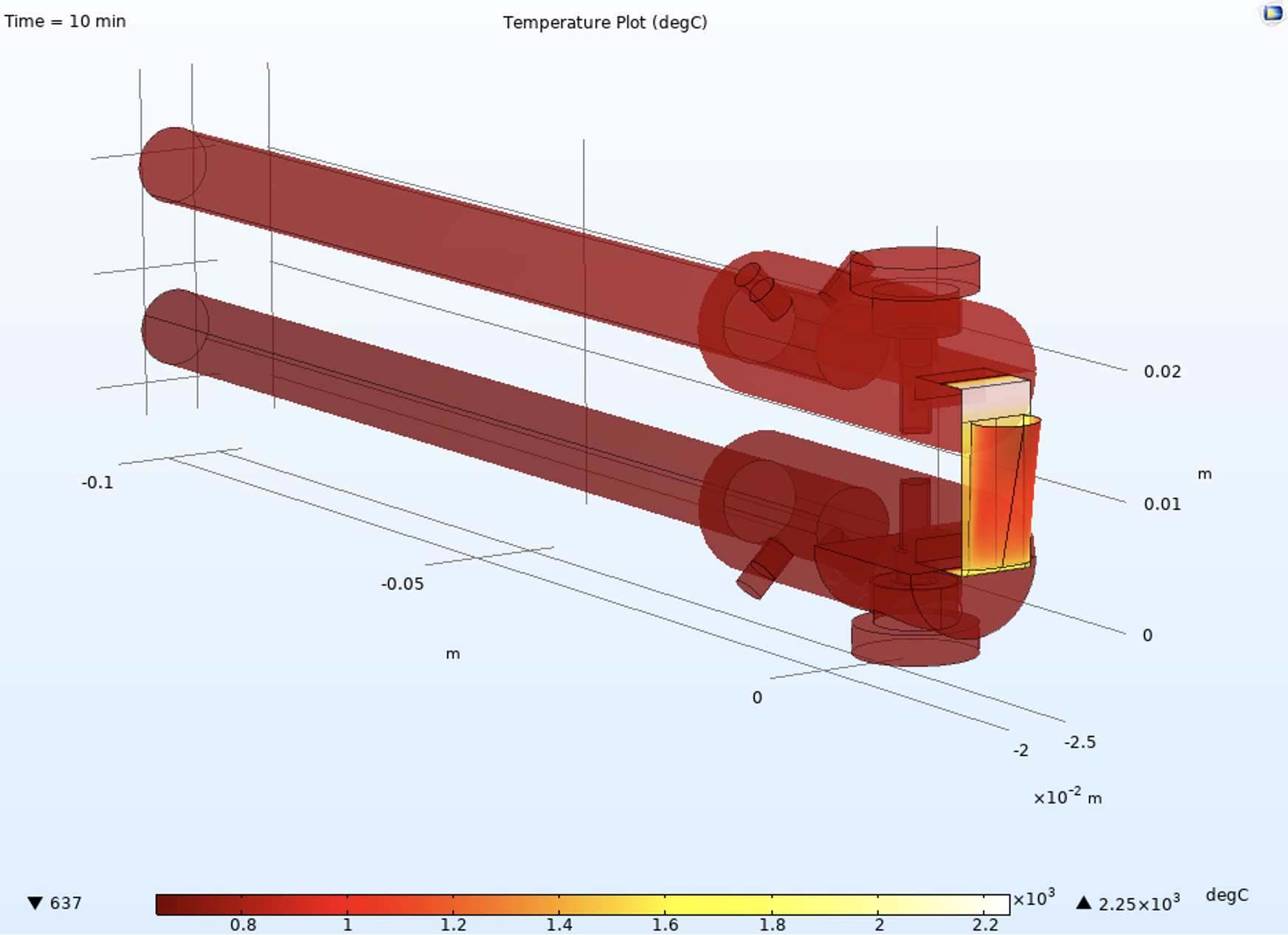

Temperature and Current Density Simulations

In order to predict any anomalous high temperature and high current concentrations due to the changed geometries of the component, FEA was performed using COMSOL: Multiphysics. The resistive heating as well as radiative effects were modeled. The results of a temperature plot can be found on the left.

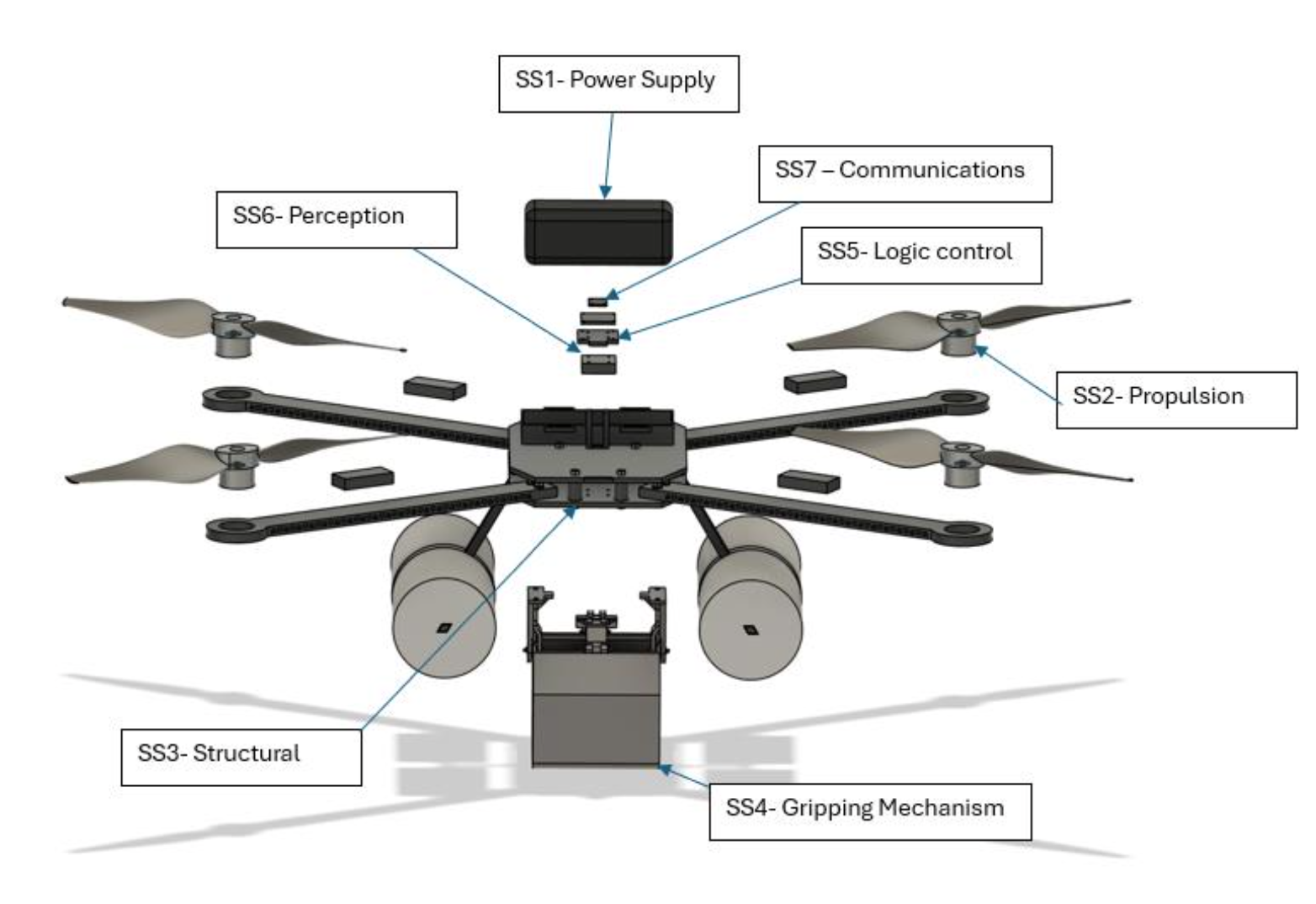

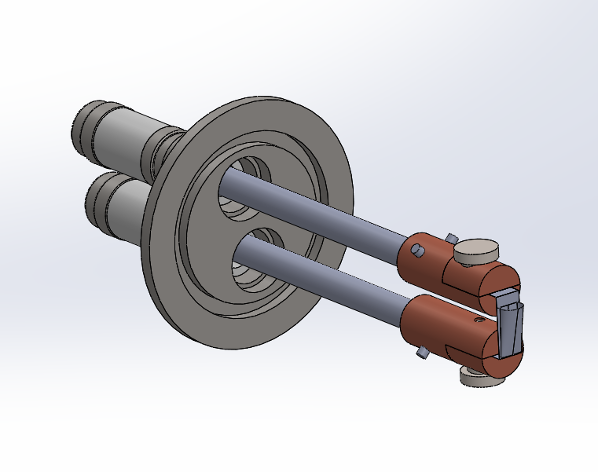

Final Model and Manufacturing

After the analysis on this part was completed, manufacturing was begun with ProtoLabs for the first physical prototype. The finalized crucible-feedthrough subassembly SolidWorks CAD model (left) and the final physical prototype (right) of this portion of my internship work can be found below.

Current-Controller Implementation

As mentioned in the abstract, a current controller device was examined in this internship. In order to perform the the laser absorption spectroscopy, this ThorLabs (Laser Diode Current Controller KLD101, pictured on the right) current controller was required to modulate the outputted laser wavelength. Several methods were experimented with; however, after many accuracy and noise tests using an optical table setup and absorption wavemeter, it was determined that the selected current controller was no suitable for this instrument's application. The design would return to a previous iterations and the casing would be reconfigured to house a larger, more suitable current controller.

Source:

Publication Link

Publication Link